Mixing Impellers

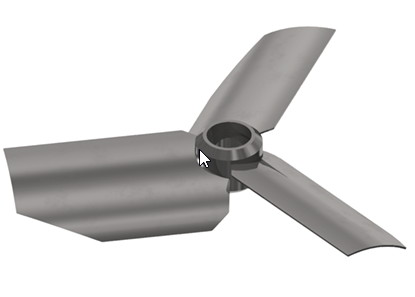

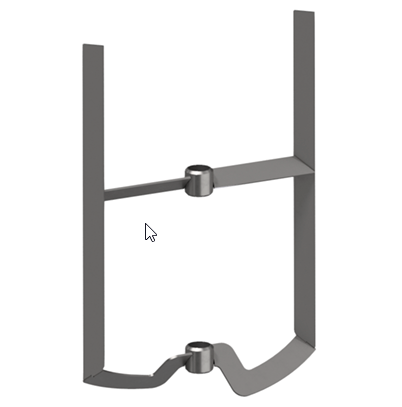

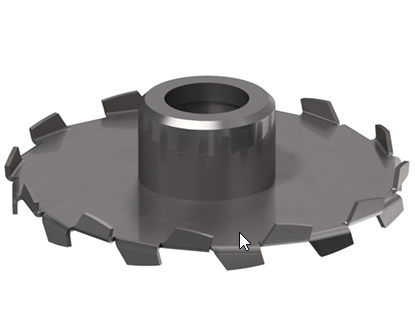

There are many types of impellers. Each impeller is unique to the type of product being mixed.

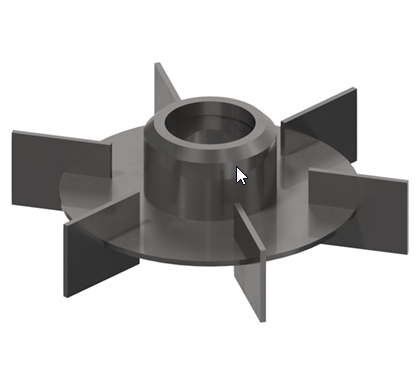

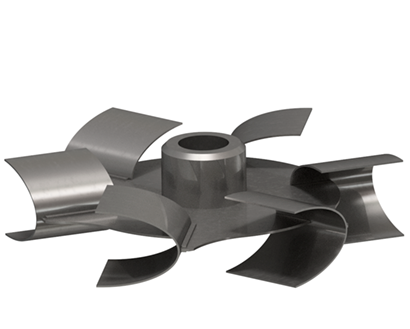

There are open impellers (turbulent mixing) and closed impellers (laminar mixing).

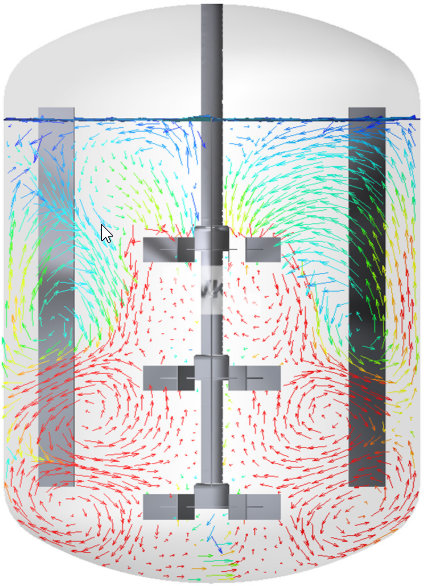

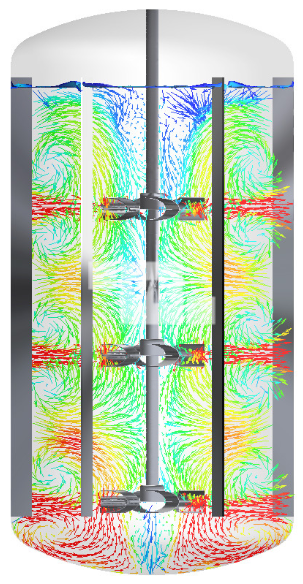

Impellers impart radial and axial mixing. Some are more axial and some are more radial.

An impeller has a unique Pumping Number (Nq) which helps to calculate the pumping capacity of the impeller in gallons per minute and hence determine the number of tank turnovers which can be achieved within a certain amount of time which we call the Blend Time.

An impeller also has a Power Number (Np) which helps us determine the power required by the impeller with respect to its design, diameter and rotation speed.

We have power number and flow numbers for many impellers found in the market place.

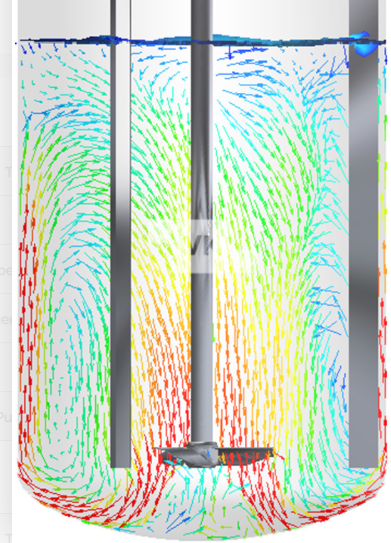

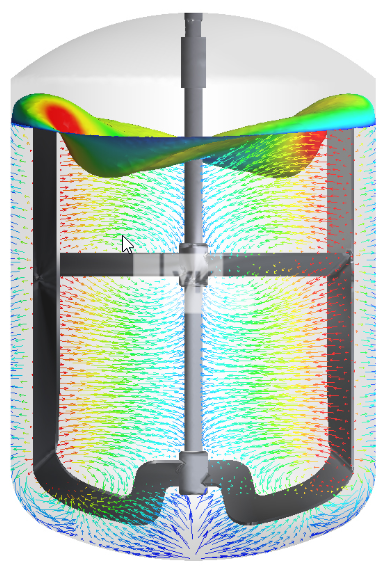

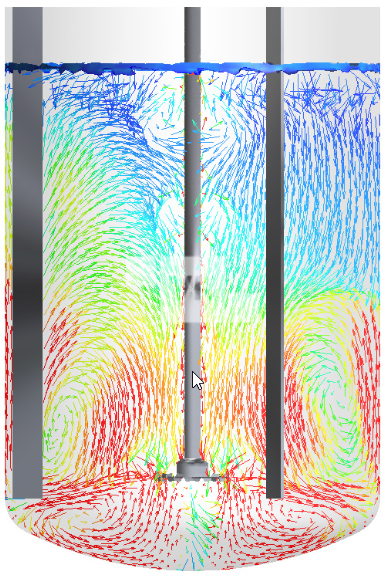

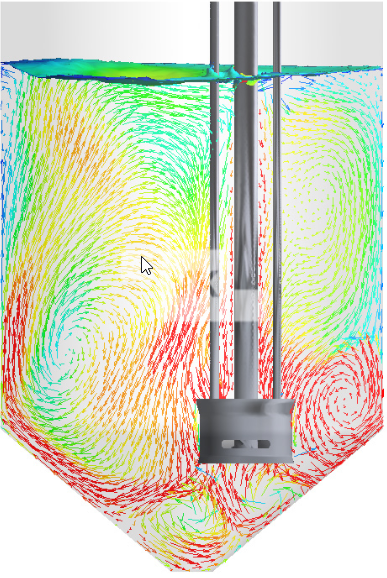

Computational Fluid Dynamics (CFD) allows for modeling the results of your mixing application and saves time in the process selection of a most efficient mixer / agitator. VFD plots courtesy of VAK KIMSA.

Axial Flow Axial Flow

Anchor viscous material Anchor viscous material

Rushton gas dispersion Rushton gas dispersion

Curved Blade gas dispersion Curved Blade gas dispersion

Cowles saw tooth high dispersion Cowles saw tooth high dispersion

Rotor Stator high dispersion Rotor Stator high dispersion

|