|

|

| |

Home >> Mixing

Guide >> Static Mixing Guide |

|

|

| |

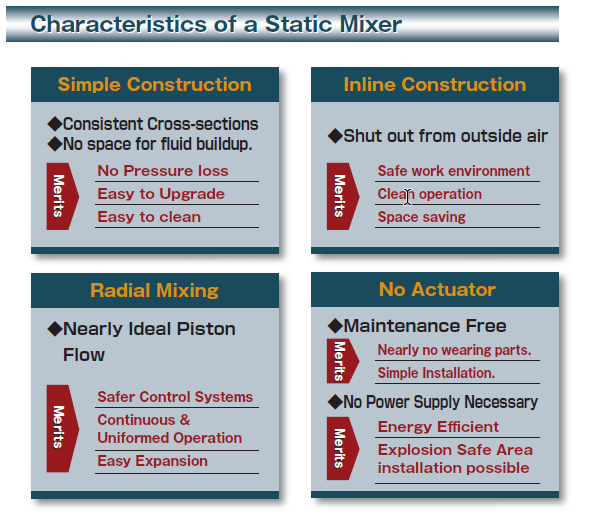

Static Mixing Guide

In this section we will discuss process and how we go about selecting the correct static mixer for your application.

Do you need an agitated tank or could you use an inline pipe static mixer?

Fluid machanics such as plug flow, reynolds number, pressure drop play a key role.

The mixer length and the number of mixing elements based on the mixing device is based on experience and laboratory studies. We will shed some light here as well.

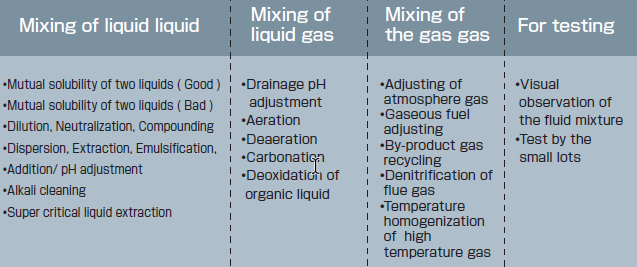

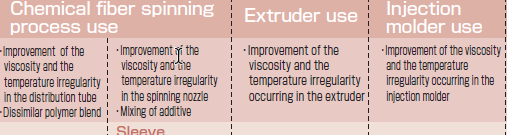

Most common application are blending of chemicals.

Dispersions, whether gas-liquid or liquid liquid are critical in some processes.

|