Glass-Lined Reactors vs. Stainless Steel: Which Is Better for Your Process?

When it comes to industrial processing, choosing the right reactor material can make or break your operations. Two of the most common options—glass-lined reactors and stainless steel reactors—each offer unique advantages depending on the application. Factors such as chemical resistance, cost, durability, and process requirements all play a critical role in determining which reactor is the best fit for your needs.

In this guide, we’ll compare glass-lined vs. stainless steel reactors to help you make an informed decision, with insights into where each type excels and where they may fall short.

What Are Glass-Lined Reactors?

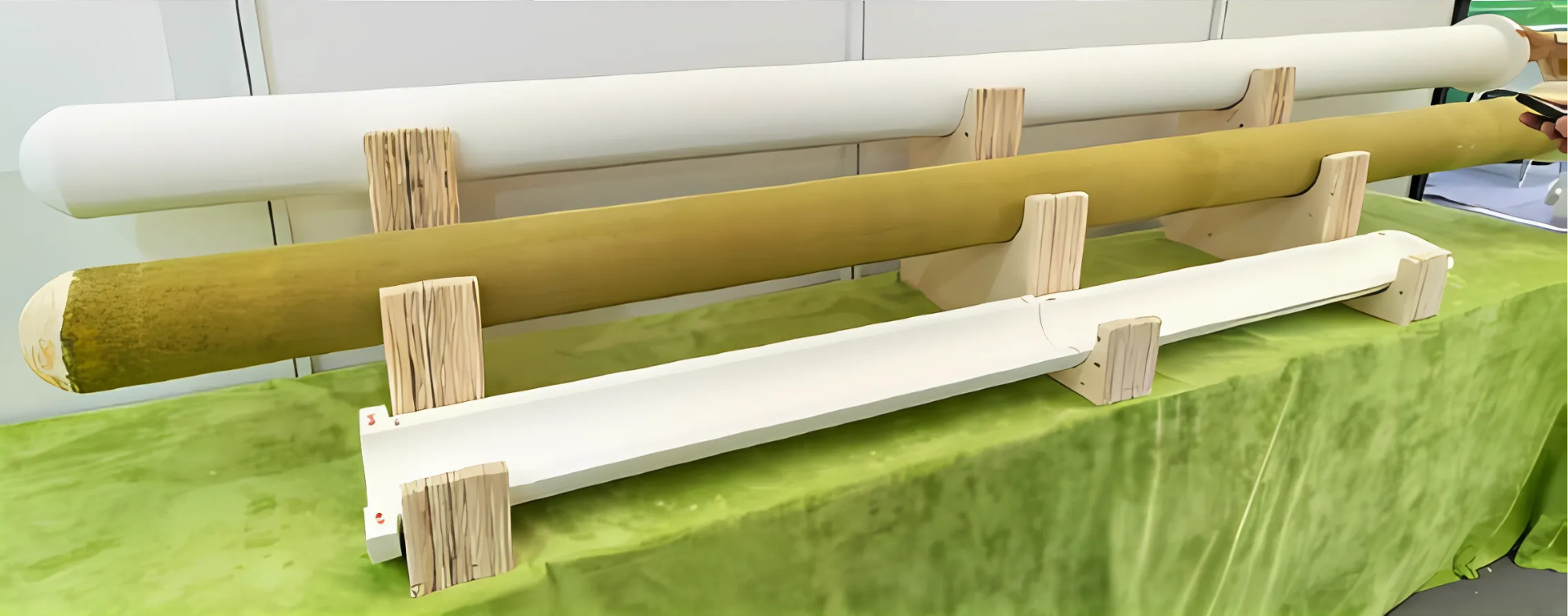

Glass-lined reactors are steel vessels coated on the inside with a layer of glass (typically fused to the metal at high temperatures). This combination provides the strength of steel with the corrosion resistance of glass. These reactors are widely used in industries like pharmaceuticals, chemicals, and food processing, where product purity and chemical inertness are vital.

Because the glass surface is smooth, non-porous, and chemically inert, it prevents unwanted reactions and contamination, ensuring consistent results in sensitive processes.

What Are Stainless Steel Reactors?

Stainless steel reactors are built entirely from stainless steel alloys, such as 304 or 316L. They are known for their strength, resistance to pressure, and ability to withstand extreme conditions. Stainless steel’s natural resistance to corrosion—particularly when combined with alloying elements like molybdenum—makes it a go-to material for industries handling aggressive chemicals or requiring sanitary standards.

These reactors are also easier to customize and weld, allowing for greater flexibility in design compared to glass-lined options.

Corrosion Resistance: Glass vs. Steel

One of the most important factors when choosing a reactor is corrosion resistance. Glass-lined reactors excel in protecting against acids, alkalis, and solvents that would quickly degrade stainless steel. They are particularly suitable for handling highly corrosive chemicals like hydrochloric acid or strong oxidizers.

On the other hand, stainless steel reactors perform better with neutral or less corrosive substances and offer greater resistance to thermal shock and mechanical stress. Choosing the right reactor often comes down to the types of chemicals you are working with.

Durability and Mechanical Strength

Stainless steel reactors generally offer superior mechanical strength. They can withstand higher pressures and temperatures without risk of cracking or damage. This makes them ideal for processes involving rapid heating and cooling or high-pressure reactions.

Glass-lined reactors, while strong, are more vulnerable to physical impact and thermal shock. However, with proper handling and maintenance, they can last for years in corrosive environments where stainless steel would corrode rapidly.

Cost Considerations

Cost is another deciding factor for many facilities. Glass-lined reactors are often more cost-effective for corrosive applications because they eliminate the need for exotic alloys or frequent replacements due to corrosion damage.

Stainless steel reactors, while sometimes more expensive upfront (especially in high-grade alloys), may be more economical in non-corrosive applications where durability and flexibility matter more than chemical resistance.

Purity and Product Quality

For industries like pharmaceuticals, biotechnology, and food processing, maintaining product purity is critical. Glass-lined reactors offer an inert surface that minimizes contamination risk and makes cleaning easier. Their smooth, non-stick surface ensures residue does not remain after cleaning, reducing the risk of cross-contamination between batches.

Stainless steel reactors, while hygienic and cleanable, may interact with certain chemicals, potentially affecting product quality. Proper passivation and maintenance are required to ensure consistent purity.

Maintenance and Lifespan

Stainless steel reactors are generally easier to repair and modify, as they can be welded, polished, and adapted on-site. Glass-lined reactors, in contrast, require specialized inspection and repair methods if damage occurs. Technologies like glass inspection and repair services can help extend their lifespan, but the repairs need to be handled by experts.

That said, with proper maintenance, both reactor types can last for decades, especially when matched correctly to their applications.

Industry Applications

- Glass-Lined Reactors: Commonly used in pharmaceuticals, specialty chemicals, food additives, and agrochemicals. Ideal for corrosive environments and processes requiring high purity.

- Stainless Steel Reactors: Widely used in petrochemicals, brewing, biotechnology, and polymer industries. Suitable for high-pressure processes, mechanical durability, and when corrosion resistance is less critical.

Environmental and Operational Efficiency

Glass-lined reactors offer efficiency in terms of reduced chemical waste and longer lifespans in corrosive environments. Stainless steel reactors contribute efficiency by handling more aggressive process conditions without cracking or breaking. Both can contribute to sustainability goals depending on how they are integrated into production processes.

How to Decide Between Glass and Stainless Steel

The decision comes down to matching reactor material with your process needs:

- Choose glass-lined reactors if you handle corrosive chemicals, require high purity, and need cost-effective long-term corrosion resistance.

- Choose stainless steel reactors if you need mechanical strength, flexibility, and resilience under pressure or rapid temperature shifts.

For some facilities, a combination of both reactor types may be the most efficient approach.

Final Thoughts

Both glass-lined reactors and stainless steel reactors offer unique benefits, and the best choice depends on your process requirements. By carefully evaluating factors like corrosion resistance, cost, purity, and durability, you can select the reactor that ensures long-term reliability and efficiency for your plant.

If you’d like to learn more about reactors and related equipment, check out our resources on Glass-Lined Reactors and Mixing Efficiency Review Services.

Have questions about selecting the right reactor for your process? Contact our team today to get started.