How Glass-Lined Mixing Equipment Supports Product Purity and Safety

When it comes to industrial processing, product purity and safety are non-negotiable. Manufacturers in industries like pharmaceuticals, chemicals, and food production must ensure their processes protect both the final product and the people handling it. One solution that has become indispensable is glass-lined mixing equipment. By combining the durability of steel with the chemical resistance of glass, these systems help companies meet strict quality, safety, and compliance standards.

In this article, we’ll explore how glass-lined mixers enhance purity, safeguard operations, and support industries where even the smallest contaminant can lead to significant consequences.

Why Product Purity Matters in Industrial Processes

Purity is more than just a selling point—it’s a regulatory and safety requirement. For example, in pharmaceutical manufacturing, the presence of even trace contaminants can alter the effectiveness of a drug. In food and beverage processing, impurities not only compromise taste but also pose serious health risks.

Using the right equipment, particularly those designed to minimize contamination risks, ensures that manufacturers consistently deliver products that meet both consumer expectations and strict industry regulations.

What Makes Glass-Lined Equipment Unique?

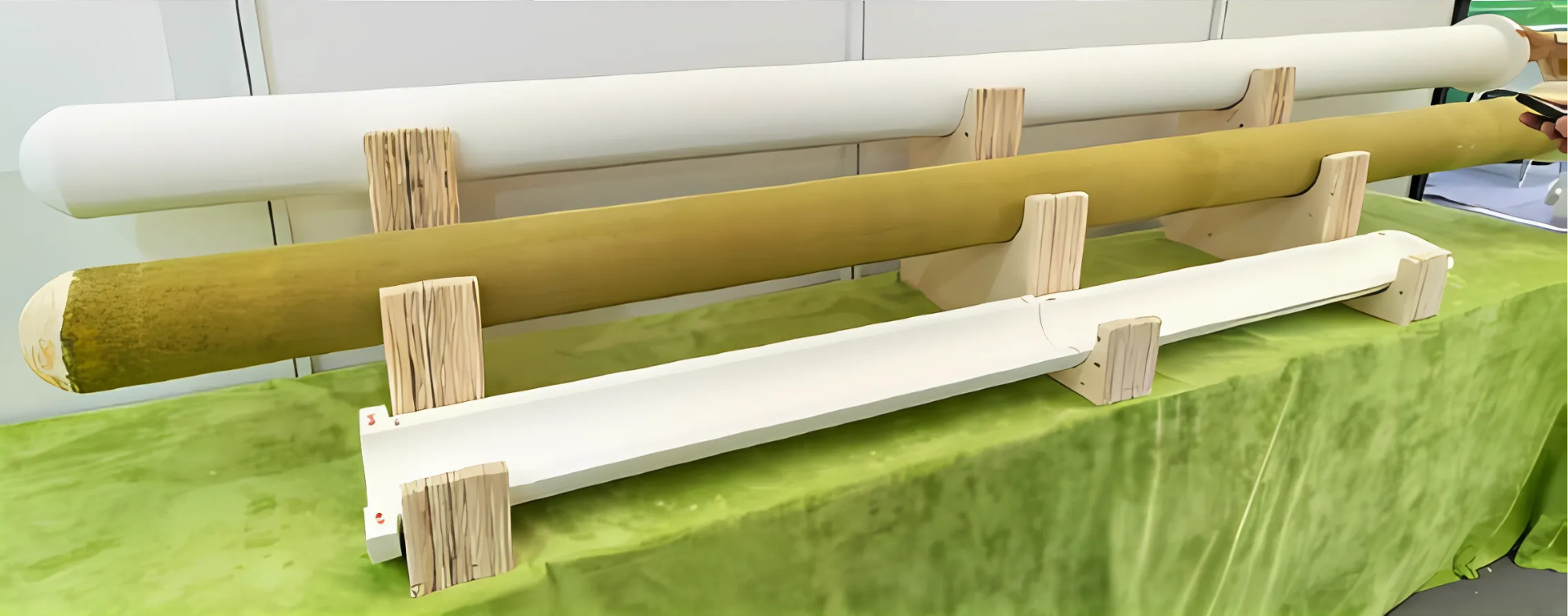

Glass-lined mixing equipment features a steel shell coated with a fused glass lining. This combination offers both mechanical strength and chemical resistance. Unlike stainless steel alone, glass linings resist aggressive acids, alkalis, and solvents while preventing unwanted reactions.

This design also creates a non-porous, smooth surface that is easy to clean and sterilize, making it ideal for operations where hygiene and product consistency are critical.

Corrosion Resistance for Long-Term Purity

One of the most important benefits of glass-lined equipment is its exceptional resistance to corrosion. Corrosion in unprotected reactors or mixers can introduce contaminants such as metal ions into the process stream. With a glass lining, the equipment forms a protective barrier, ensuring no corrosion byproducts enter the product.

For instance, chemical plants that work with aggressive acids often rely on glass-lined reactors to avoid cross-contamination and extend equipment life.

Maintaining Chemical Inertness

Glass is inherently chemically inert, meaning it doesn’t react with the process media. This ensures that sensitive products remain unchanged throughout production. Unlike metals, which can catalyze unwanted side reactions, glass-lined surfaces maintain the stability of formulations.

Consider pharmaceutical mixing: the inert surface of glass-lined mixers ensures drug compounds maintain their intended chemical structure, protecting both efficacy and patient safety.

Enhanced Cleaning and Sterilization

Cleaning challenges often lead to hidden contamination risks. Glass-lined equipment reduces this risk by offering a smooth, non-stick surface. Residues, powders, or sticky substances are less likely to cling to the lining, making cleaning faster and more effective.

This is especially critical in industries with strict batch-to-batch separation, such as pharmaceuticals, where residue from one drug must not affect the next production run.

Safety Benefits for Operators

Beyond product safety, operator safety is also a key concern. Corrosion, leaks, or material buildup in poorly designed equipment can expose workers to hazardous chemicals. Glass-lined mixers minimize this risk by providing an additional protective layer between aggressive chemicals and the external environment.

Combined with proper maintenance and inspection, glass-lined equipment helps ensure a safer working environment for plant personnel.

Real-World Applications of Glass-Lined Mixers

Glass-lined mixing equipment is widely used in chemical synthesis, polymer production, pharmaceutical formulation, and food manufacturing. Each application leverages the ability of glass to maintain purity and withstand demanding processing conditions.

For example, a pharmaceutical company producing antibiotics might choose a glass-lined reactor to avoid contamination by metal catalysts, ensuring a purer and safer product.

Comparing Glass-Lined to Stainless Steel Mixing Equipment

While stainless steel is a common choice for many industries, it is not always the best solution for purity and safety. Stainless steel can corrode or leach ions into the product under certain conditions, especially when exposed to strong acids or bases.

Glass-lined equipment, by contrast, excels in environments where chemical resistance and inertness are critical. Choosing the right equipment often depends on the balance of cost, process requirements, and long-term safety.

Extending Equipment Lifespan with Proper Care

Like any specialized equipment, glass-lined mixers require regular inspection and maintenance to ensure their effectiveness. With proper care, they can operate for decades without compromising performance. Damage detection systems and repair services, such as glass inspection and repair, further extend the lifespan of these valuable assets while protecting product purity.

For more, you can explore our Glass Inspection & Repair Services.

Regulatory Compliance and Industry Standards

In industries where compliance with FDA, EMA, or ISO standards is essential, glass-lined mixing equipment provides a reliable path to meeting these requirements. Its hygienic design, corrosion resistance, and ability to preserve product integrity support companies in passing audits and maintaining certifications.

This not only ensures legal compliance but also builds trust with consumers and stakeholders.

Conclusion: Why Glass-Lined Mixing Equipment is Essential

In industrial applications where safety and purity are paramount, glass-lined mixing equipment stands out as a critical solution. Its ability to resist corrosion, prevent contamination, and support strict compliance makes it invaluable across chemical, pharmaceutical, and food sectors.

If you’re looking to enhance your process safety and protect product purity, ZAIN can help. Reach out today to learn more about our glass-lined equipment solutions and consulting services.