ZAIN's Blogs

We'll take care of all your industrial mixing challenges, so you can focus on production efficiency.

September 11, 2025

In today’s industrial landscape, sustainability and efficiency are top priorities. From power generation to chemical processing, companies are under pressure to reduce emissions while maintaining operational productivity. One of the most effective solutions for achieving these goals is the ceramic catalytic filter . These advanced filtration systems combine the durability of ceramic materials with catalytic coatings to capture dust and remove harmful gases in a single step. In this guide, we’ll explore the key benefits of ceramic catalytic filters in industrial applications , highlighting how they improve air quality, reduce costs, and create safer, more efficient plants.

September 4, 2025

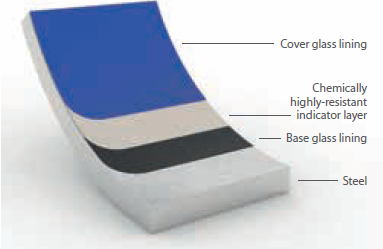

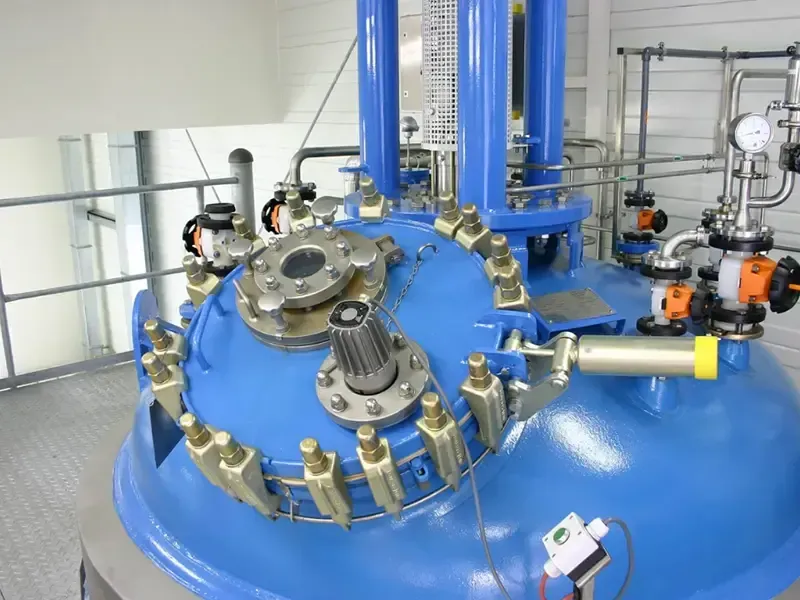

When it comes to industrial processing, product purity and safety are non-negotiable. Manufacturers in industries like pharmaceuticals, chemicals, and food production must ensure their processes protect both the final product and the people handling it. One solution that has become indispensable is glass-lined mixing equipment . By combining the durability of steel with the chemical resistance of glass, these systems help companies meet strict quality, safety, and compliance standards. In this article, we’ll explore how glass-lined mixers enhance purity, safeguard operations, and support industries where even the smallest contaminant can lead to significant consequences.

August 28, 2025

When it comes to industrial processing, choosing the right reactor material can make or break your operations. Two of the most common options— glass-lined reactors and stainless steel reactors —each offer unique advantages depending on the application. Factors such as chemical resistance, cost, durability, and process requirements all play a critical role in determining which reactor is the best fit for your needs. In this guide, we’ll compare glass-lined vs. stainless steel reactors to help you make an informed decision, with insights into where each type excels and where they may fall short.

August 21, 2025

In industries where high-temperature processes release dust, harmful gases, and fine particulates, finding an efficient filtration solution is essential. Ceramic catalytic filters have emerged as one of the most advanced technologies for hot-gas filtration, providing durability, multifunctional performance, and compliance with strict emission regulations. This guide explains what ceramic catalytic filters are, how they work, and why they’re becoming the preferred choice for modern industrial plants.

August 14, 2025

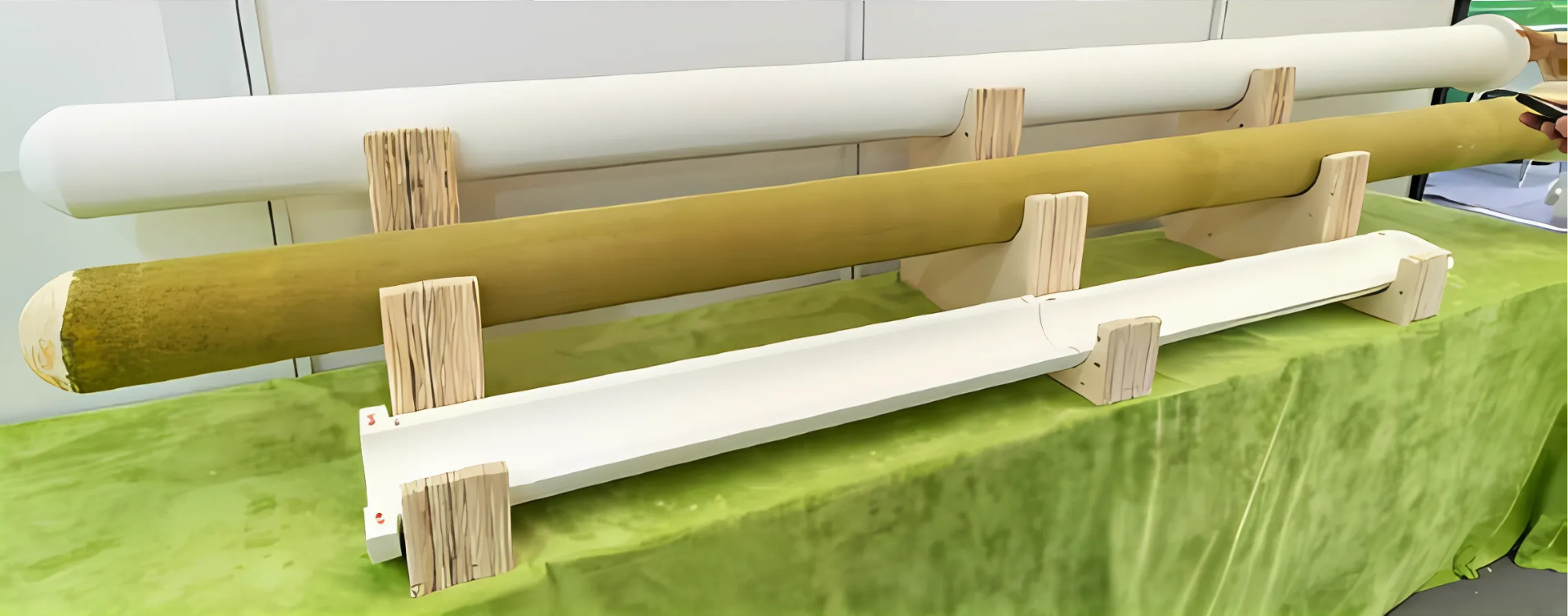

Selecting the right mixing equipment is one of the most important technical and financial decisions you’ll make for a process line. The choice between glass-lined and standard (stainless steel / specialty alloy) mixing equipment affects product purity, maintenance, operating cost, regulatory compliance, and long-term reliability. This guide walks you through the practical tradeoffs, real-world scenarios, and a clear decision checklist so you can pick the equipment that best fits your process requirements.

July 31, 2025

Glass‑lined mixers offer a powerful combination of chemical resistance, operational safety, and long-term cost efficiency. In this guide, we explore how glass‑lined mixing technology delivers outstanding value across corrosive processing environments in pharma, chemicals, food, and specialty industries.

July 24, 2025

Glass-lined reactors play a crucial role in pharmaceutical production due to their corrosion resistance, purity maintenance, and ease of cleaning. This guide explores the core benefits of glass-lined reactors in pharma, their design considerations, real-world applications, and how they contribute to regulatory compliance and operational efficiency.

July 17, 2025

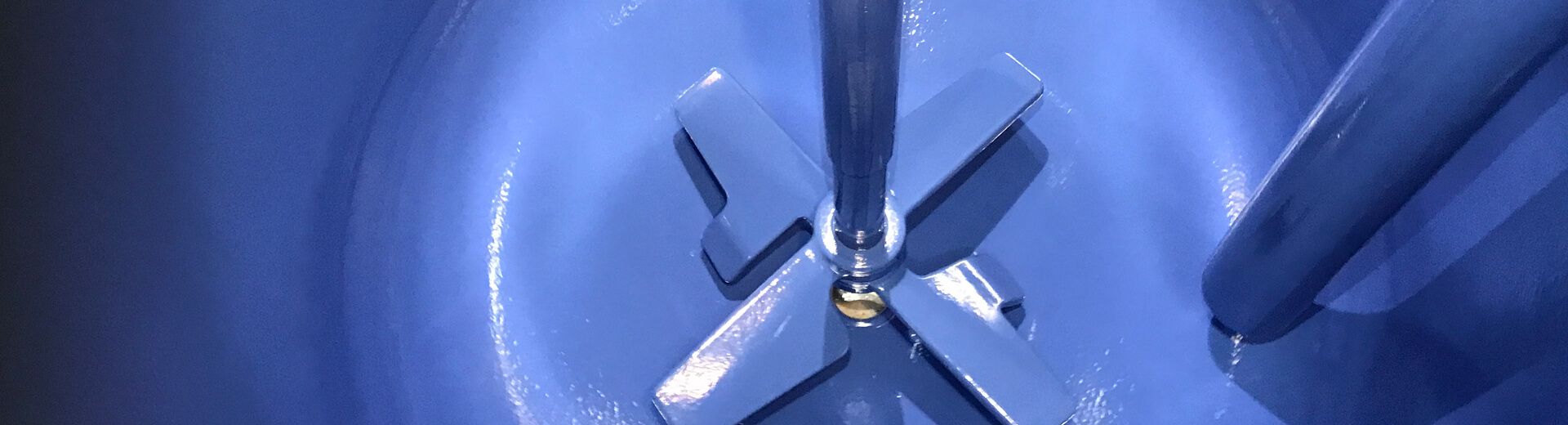

Glass-lined mixing equipment—including reactors, tanks, and agitators—combines chemical resistance with mechanical reliability. In this beginner’s guide, we examine how glass-lined systems work, why they are essential in corrosive environments, and how to use and maintain them for optimal performance.

July 10, 2025

Glass-lined reactors have become indispensable in chemical processing thanks to their superior corrosion resistance, purity, and versatility. In this comprehensive guide, we'll explore what makes these reactors unique, the core benefits they offer, typical applications, and key considerations when choosing the right glass-lined vessel for your process.

July 2, 2025

The advent of 3D printing—also known as additive manufacturing—has sparked a revolution in industrial design, enabling engineers to create complex, optimized mixing components previously deemed unmanufacturable. In mixing technology, this innovation is more than a novelty—it enhances performance, saves cost, and accelerates development cycles. In this article, we explore how 3D printing reshapes the design of mixing equipment parts like impellers, static mixers, and micro-reactor elements, and what this means for industries ranging from pharmaceuticals to 3D printing materials themselves.

June 26, 2025

Proper maintenance of mixing equipment is essential for maximizing performance, reducing downtime, and extending service life. Whether you're operating ribbon blenders, industrial agitators, or high-shear mixers, proactive care can save you time, money, and hassle. Below are key strategies to keep your mixing systems in top condition.

June 19, 2025

Pharmaceutical manufacturers face stringent quality requirements, tight timelines, and ever-evolving formulations. Advanced mixing equipment plays a pivotal role in ensuring consistent product quality, efficient processing, and regulatory compliance. This guide dives deep into how modern mixing technologies can optimize pharmaceutical production, exploring critical design features, process validation, monitoring strategies, and real-world examples that illustrate the tangible benefits of investing in the right equipment.

June 12, 2025

Mixing equipment is undergoing a transformative shift as automation and IoT (Internet of Things) technologies reshape industrial processes. Today’s manufacturers seek smart solutions that deliver consistent product quality, reduce downtime, and enable data-driven decision-making. In this comprehensive guide, we explore how mixing equipment evolves through automation and IoT integration, the benefits and challenges of adoption, real-world examples, and steps to implement smart mixing systems. By understanding these trends, process engineers and decision-makers can position their operations for greater efficiency and competitiveness.

June 5, 2025

In industrial processing, selecting the appropriate mixing equipment is crucial for product quality, operational efficiency, and cost-effectiveness. Two primary categories of mixers—static and dynamic—serve diverse applications across industries such as food and beverage, pharmaceuticals, chemicals, and adhesives. Understanding the distinctions between these mixing technologies is essential for optimizing your process.

May 29, 2025

In the realm of industrial processing, especially within the food, pharmaceutical, and cosmetic sectors, achieving the desired product texture is paramount. A critical factor influencing texture is the shear rate applied during mixing. This article delves into the concept of shear rates, their impact on product texture, and how different mixing equipment can be optimized to achieve consistent and high-quality results.

May 22, 2025

In the dynamic world of food and beverage production, mixing equipment plays a pivotal role in ensuring product safety, consistency, and flavor. From blending sauces to homogenizing dairy products, the right mixing solutions are essential for delivering high-quality consumables that meet both regulatory standards and consumer expectations.

May 15, 2025

What Is Mixing Equipment? A Beginner’s Guide to Industrial Blending Solutions Mixing equipment is a cornerstone of industrial manufacturing, ensuring consistent product quality across various sectors. From pharmaceuticals to food processing, the right blending solutions are crucial for efficient and effective production. This guide delves into the essentials of industrial mixing equipment, helping beginners understand its significance, types, and applications.