Expert Mixing Solutions Consulting Services

Optimize Your Mixing Processes with ZAIN Technologies

At ZAIN Technologies, we specialize in mixing solutions consulting services to help businesses improve efficiency, reduce costs, and enhance performance. With decades of industry experience, we provide tailored solutions for OEMs, process equipment manufacturers, and industrial users looking to optimize their mixing operations.

Why Choose ZAIN for Mixing Solutions Consulting?

- Unbiased Equipment Selection – We stay up to date with the latest mixing technologies across industries to recommend the best solutions.

- Cost Reduction Strategies – Our consulting helps businesses cut operational expenses while improving mixing efficiency.

- Process Optimization – We analyze and refine existing mixing applications to enhance productivity and performance.

- Market Expansion Support – For manufacturers seeking to enter new industries, we provide expert guidance on sales strategies and business development.

- Industry-Leading Expertise – With over 30 years of experience and access to global mixing technology experts, we deliver proven results.

Our Comprehensive Mixing Solutions Consulting Services

Mixing Equipment Evaluation & Selection

We assess various mixing equipment options from top suppliers, ensuring you get the best performance at the lowest cost.

Process Optimization & Efficiency Improvements

Our experts analyze your current processes and recommend adjustments to increase productivity and reduce waste.

Mixing Equipment Market Research & Strategy

We provide insights into industry trends, competitive analysis, and sales strategies to help manufacturers grow their market share.

Customized Training & Technical Support

We offer technical training seminars to educate teams on mixing fundamentals, equipment selection, and process improvements.

Explore Our Comprehensive Mixing Guides

Enhance your process performance with our detailed guides. Choose from two categories below:

Mixing Guides

- Static Mixing Guide: Learn best practices for inline mixing applications.

- Dynamic Mixing Guide: Discover essential insights into agitator-based mixing systems.

Mixing Equipment Guides

- Static Mixing Equipment Guide: Find expert advice on selecting and installing static mixers in piping systems.

- Dynamic Mixing Equipment Guide: Get practical tips on choosing and sizing dynamic agitators and related hardware.

Use the buttons below to access each guide and take your mixing process to the next level.

Industry Insights: The Global Mixing Equipment Market

The Growing Demand for Fluid Mixing Equipment

Fluid Mixing is a critical unit operation in many process plants.

In North America, there are over 2 billion dollars worth of mixing equipment in operation. According to one major supplier of mixing equipment "......over 30,000 spiral bevel reducers are running in mixing operations across the USA within the past few years...".

It is estimated that in the USA about 450 Million dollars of mixing equipment is purchased in one year. Worldwide close to 1 Billion US dollars of mixing equipment are purchased in one year.

Key Players in the Mixing Equipment Industry

Mixing is a core unit process.

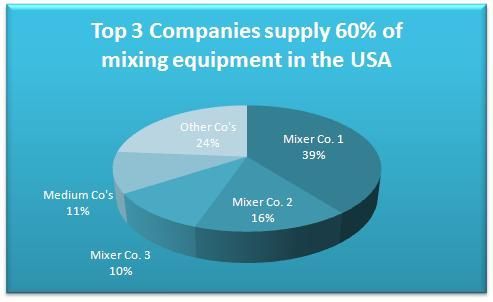

Currently, there are three major suppliers in the USA and about 15 to 20 medium suppliers. The three major suppliers have at least 60% market share.

Understanding Mixing Equipment Categories

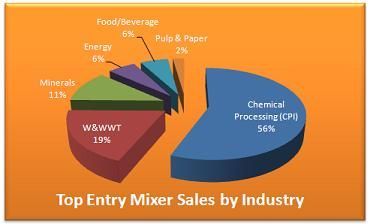

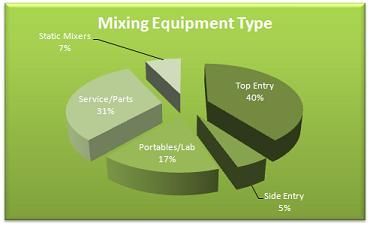

Mixing Equipment is categorized as Dynamic Mixers (Top Entry, Side Entry, Portable/Lab and Spare Parts, etc.) and Static Mixers (Inline mixers, static mixers, heat exchangers, and cooling reactors that use static mixers for viscous products). In the USA, the breakdown is estimated to be as shown on the figure.

Note: Static Mixers does not include for Disposable Static Mixers in the figure

Navigating the Mixing Equipment Market

At ZAIN, our goal is to educate you on mixing technology and let us assist you in choosing your mixer supplier without necessarily having to rely solely on the top three mixing equipment suppliers in the USA.

Sales and Distribution channels used for mixing equipment. Heavy reliance on Sales Representative offices. These are indirect companies that sell mixing equipment based on commission. Typical commissions paid out to sales representatives are in the range of 10-15% of the selling price. Larger, more complex projects are typically handled directly by the equipment fabricator due to the complexity of the technology used. In this case, sales reps can get as low as 1-3% commission. Portable/Lab mixers are also sold via catalog houses, where they can make as much as 20% for reselling the equipment. Sales representatives with a good understanding of mixing technology and strong relationships with end users tend to be most successful.

USA where used: California, Illinois, Texas, and New York are heavy users of mixing equipment. Interestingly, you will also find the most chemical engineers also employed in these states.

PRICE MARGIN EROSION: Interestingly, in the USA, as competition is fierce and the USA customer wants the best value at the lowest cost, we are watching the mixer suppliers margins decline, and hence they are working harder to reduce costs and streamline their designs. The lower the end user pays for the equipment just means less money is being spent in marketing and R&D activities.

Variable Margins VM: Process mixing equipment companies in the USA average in the range of 30-45% margins, sell price vs. cost (where cost is the sum of labor, material, and manufacturing overhead). In highly competitive situations, they can go as low as 10-15%, or at cost, if deemed a strategic entry to a market or a particular customer. In non-competitive situations, the margins can be as high as 60%.

ZAIN Technologies offers the option to educate the end user on mixing technology and equipment design so that the end user has even more control over the price and value when purchasing mixing equipment.