Industrial Mixing Equipment Guide

This guide covers the essential hardware required for the agitator or static mixer you need to perform the mixing task in your process. Whether you’re setting up a dynamic agitation system or installing a static mixer in your piping, having the right equipment is crucial for optimal performance and longevity.

Essential Components for Agitators

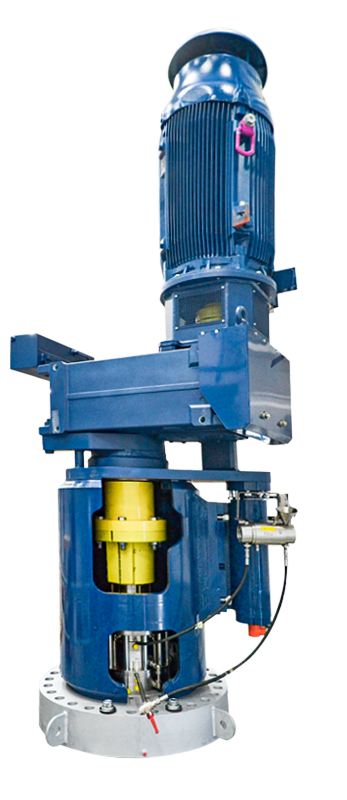

Agitator Hardware Requirements

Agitators require a reliable power source—whether air-operated, electric, or hydraulic—to drive the mixing process. Key components include:

- Power Supply: Choose the appropriate power type based on your process needs.

- Gearbox Design & Selection: Ensure the gearbox is designed to handle the required torque and speed reductions efficiently.

- Bearings: Select bearings that provide the correct bearing life and can withstand the forces imparted by the rotating shaft and impeller thrust.

- Shaft & Impeller Design: The design of the shaft and impeller is critical for achieving effective mixing and minimizing maintenance issues.

Using high-quality materials of construction will not only enhance the durability of your agitator but also ensure successful mixing results.

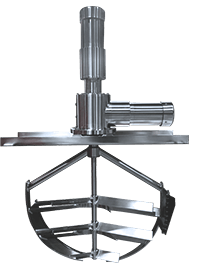

Static Mixer Design Essentials

Static mixers are more straightforward compared to agitators. They are mixing devices installed directly inside a pipe with end connections and an injection point. Key points to consider include:

- Installation: Static mixers are integrated within piping systems, making them ideal for continuous mixing without moving parts.

- Injection Point: Ensure the injection point is strategically placed for optimal mixing performance.

- Material Selection: As with agitators, using the correct materials of construction will ensure longevity and reliable performance in your static mixer.

Explore More Specific Guides

Delve deeper into our expert resources with our detailed guides designed to help you optimize your mixing equipment selection and performance. Whether you’re looking for static or dynamic solutions, our guides provide practical insights and technical tips to meet your process requirements.

Learn about design considerations, installation best practices, and material selection for optimal performance in continuous processes.

This guide covers everything you need to know about selecting and sizing dynamic mixing equipment for superior agitation and process efficiency.

Approval Drawing & Communication Best Practices

One common issue during the equipment selection and fabrication process is miscommunication during the approval drawing phase. To avoid costly mistakes:

- Detailed Review: Both parties must carefully review the drawings before fabrication begins.

- Clear Communication: Ensure that all technical details and specifications are clearly communicated and agreed upon during the approval process.

By following these guidelines and ensuring a thorough understanding of the hardware requirements, you can achieve optimal mixing performance and long-term equipment reliability.

For more detailed information, check out our comprehensive guides on Static Mixing and Dynamic Mixing.

Discover best practices, design tips, and sizing criteria for static mixers in continuous and batch processes.

Learn how to select, size, and optimize dynamic mixers to achieve superior agitation and process performance.

Mixing Equipment Examples

Mixing equipment is available in many design configurations with just as many vendors.