Expert Consulting for High Shear Mixing Agitators

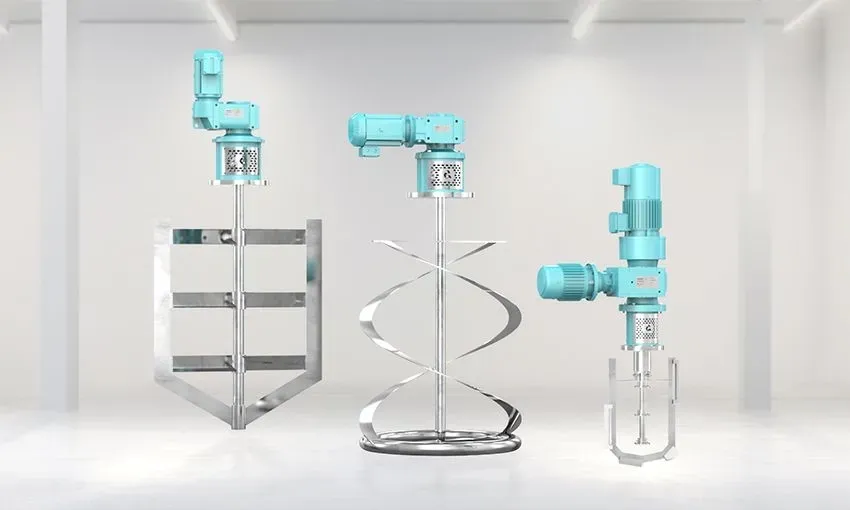

ZAIN—Your Consultant for

High Shear Mixing Agitators

We specialize in helping you specify, evaluate, and optimize High Shear Mixing Agitators tailored to corrosive, high-purity processing—without pushing product or sales.

Why High Shear Mixing Agitators Matter

- Rapid Homogenization & Emulsification — They create intense shear forces that break down agglomerates and disperse powders or immiscible liquids quickly to give fine, stable emulsions or suspensions.

- Improved Product Consistency & Quality — By achieving uniform particle or droplet sizes and eliminating dead zones, they ensure each batch meets strict quality standards.

- Shorter Processing Times & Higher Throughput — These agitators reduce mixing and dispersion time dramatically compared to conventional mixers, increasing production rates.

- Versatility Across Formulations & Viscosities — High-shear agitators can handle low to moderate, and often high, viscosities; used in emulsions, pastes, powders, etc.

- Reduced Waste & Energy Consumption — More efficient mixing means less over-processing, less raw material waste, and lower power usage per unit of output.

Our Consulting Services

Needs Assessment

We analyze your product formulation (emulsions, suspensions, dissolutions), fluid properties (viscosity, shear sensitivity), throughput, temperature, and mixing goals to define the ideal high-shear agitator setup.

Specification Development

We help build detailed RFQ packages with specs such as rotor-stator or dispersion disk types, tip speed, power, material compatibility, cooling/heating requirements, and cleanability (CIP/SIP) needs.

Vendor Review & Bid Evaluation

We objectively compare high-shear agitator proposals — evaluating performance, power draw, mechanical reliability, vendor support, and total cost of ownership — to identify the best value.

Performance Analysis

We assess your existing or proposed agitator systems, advising on improvements in mixing uniformity, emulsification quality, dispersion speed, energy efficiency, and minimizing wear or maintenance.

Technical Training & Knowledge Transfer

We provide hands-on training to your staff on startup, control-of shear rates, cleaning/sterilization procedures, maintenance, operational troubleshooting, and how to scale from pilot to production reliably.

Who We Work With

Chemical processors working with aggressive chemistries.

Pharmaceutical and biotech plants needing regulatory-grade purity.

Food and biotech sectors leveraging glass-lined assets.

OEMs and engineering firms that design or integrate reactors and vessels.

How ZAIN Adds Value

1

Unbiased guidance—we don’t sell equipment, only provide expert analysis.

2

Technical authority—we ensure mixing and vessel specs are optimized for your process.

3

Cost savings—we negotiate bids to save on capital, operating, and maintenance expenses.

4

Experience-driven—industry knowledge drawn from global glass-lined reactor integrations.

Why Choose ZAIN for High Shear Mixing Agitators Consulting?

Choosing ZAIN for high shear mixing agitators consulting means partnering with experts who understand the unique challenges of handling corrosive chemicals and high-purity processes. With years of experience, ZAIN helps optimize the performance, safety, and longevity of your high shear mixing agitators to ensure maximum efficiency.

Our consulting services cover everything from selecting the right high shear mixing agitators to vendor evaluation, bid assessment, and process optimization. We also provide hands-on training so your team can confidently operate and maintain the high shear mixing agitators , minimizing downtime and operational risks.

By working with ZAIN, you get a partner dedicated to enhancing productivity and reliability across your operations, ensuring that every piece of high shear mixing agitators performs at its best.

Frequently Asked Questions

Discover everything you need to know about ZAIN Industries—from our innovative industrial mixing solutions and expert consulting services to practical answers on process optimization and how to contact our team.

Who is ZAIN Industrial?

ZAIN Industrial is a leading expert in industrial mixing solutions. We specialize in providing consulting services, Mixing tanks and reactors as well as Field Services.

What services do you offer?

We offer optimum mixing equipment design and selection from innovative suppliers. Onsite glass repair and preventative maintenance. Optimization of your existing mixing processes.

Which industries do you serve?

Our expertise spans a wide range of industries, including specialty chemicals, pharmaceuticals, water and wastewater, paints and adhesives. We tailor our solutions to meet the unique needs of each industry.

How can I access your mixing guides?

What makes your mixing solutions unique?

At ZAIN Industrial, we combine decades of industry experience with a commitment to transparency and innovation. Our unbiased approach ensures that you receive the best recommendations, helping you save time and money while optimizing your process.

How do you ensure the quality of your consulting services?

We work as part of your team, thoroughly reviewing process requirements and equipment specifications. Our expert consultants conduct third-party reviews to guarantee that every recommendation meets industry standards and delivers optimal performance.

How can I request a consultation or more information?

For personalized advice we will assist you in writing the request for quote by understanding your process needs. Visit our Contact page. Our team is always ready to assist you with your mixing technology needs.

Where can I learn more about your company?

Visit our About page to learn more about ZAIN Industrial. We invite you to explore our website and discover how we can help improve your process efficiency.