The pages within this guide.

Blending

Fluid Blending covers a wide range of application areas, from gas mixing and turbulent liquid blending to laminar blending operations.

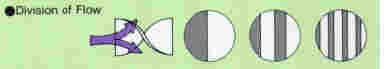

Laminar Fluid Blending relies on the buildup of layers or striations of fluid by a combination of a splitting and rotating action of the mixing elements.

The thickness of the striations, d, can be defined as shown following:

where D is the inside diameter of the pipe, and N is the number of elements.

Turbulent flow conditions increase the intensity of radial mixing in a static mixer, allowing much shorter mixing lengths. Turbulent flow in an empty pipe occurs at a Reynolds number of approximately 2000; however, in a static mixer, turbulence will develop at a much lower Reynolds number due to the increased velocities caused by the elements. Turbulence will develop at a Reynolds number of 1000.

Radial Mixing...

- Creates both macro-scale and micro-scale turbulence with total stream inversion. Eliminates radial gradients of fluid properties such as concentration, temperature, density, and velocity.

- Creates a residence time distribution that more closely approaches true plug flow when compared with empty pipes or agitated tanks.