The pages within this guide.

Dispersion

Immiscible Fluids can be dispersed in a static mixer operating in turbulent flow. This creates a solution of small droplets of the dispersed phase in the continuous phase.

The use of static mixers allows for accurate prediction of drop sizes, which can help with mass transfer calculations, etc.

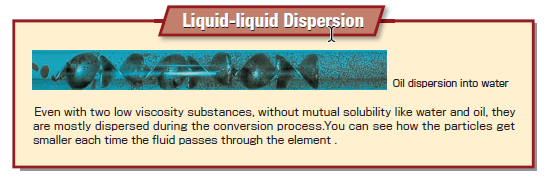

Liquid-Liquid Dispersion

Dispersion can be considered a mixing of two or more immiscible liquids into a pseudo-homogeneous mass. Small droplets are created to provide contact between the two phases. The reason for this can be to extract a solvent, to remove or clarify color, to add or remove heat, or to affect mass transfer rates. Common applications are to disperse water and hydrocarbons and acidic or alkaline solutions combined with organic liquids.

The term's dispersion and emulsion are often used interchangeably. However, for clarity, a dispersion is a term implying distribution, whereas an emulsion is a special case of a dispersion where the resulting mix is relatively stable with respect to time.

A dispersion, on the other hand, is a 2-phase mixture in which drops may coalesce. The material generally present in the larger quantity is called the continuous phase, while the material formed into droplets is the dispersed phase. The stability of an emulsion depends on the surface ion activity, which is a function of particle size (small particles have a larger total surface). Small particles weigh less and so require fewer surface ions to emulsify them.

Turbulent conditions ensure a high-intensity radial mixing action in a static mixer. For proper dispersion calculations, assume that turbulence will develop at a Reynolds number of 5000.

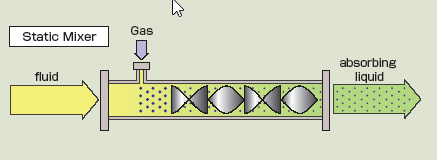

Gas-Liquid Dispersion

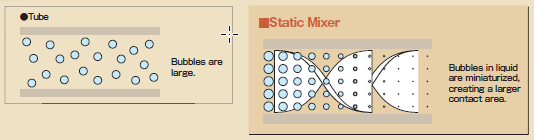

Dissolving gas into liquids. via low heat and high pressure. Bubbles inside the static mixer are into fine droplets. Increases dissolution efficiency. Used in aeration processes, carbonic acid gas absorption process in beverages. Ammonia gas into water to create water and many other applications.

The process of absorbing gas into a liquid requires you to increase the absorptivity of the gas by dispersing the gas into small bubbles and increasing the interfacial contact area. The stirring effect of the static mixer makes the bubbles finer and disperses them uniformly. Moreover, continuous elements repeat the dispersion process, renewing the gas-liquid interfacial area. This creates more efficient gas absorption. The general-use static mixer supports a liquid-to-gas ratio of up to 1:2.5.